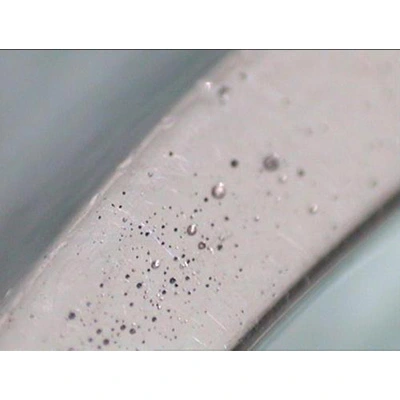

Methods to reduce porosity in aluminum die-casting products

Ensure the refining and degassing quality of aluminum alloy smelting, and select a good refining agent and degassing agent to reduce the gas content in the aluminum water. Remove the scum, bubbles, and other oxides on the liquid surface in time to prevent the gas from entering the die-casting parts again.

Choose a great release agent. The selected release agent should not generate gas during the die-casting process and has good release performance.

Ensure that the exhaust of the mold is unobstructed, and ensure that the gas in the mold is completely exhausted, especially the exhaust channel for the final polymerization of the aluminum liquid.

Adjust the die-casting parameters, and the filling speed should not be too fast to prevent air entrainment.

Pay attention to the use of core pulling and cooling in product design and mold design to minimize the shortcomings of excessive wall differences.

The pores that often appear in the fixed position should be improved from the mold and design.

Features

1. Small heat-affected zone

Due to the millisecond pulse discharge time, the precise energy control (small solder joint 1.6-2.0mm) does not affect the area outside the welding area. Achieve a cold welding effect without thermal deformation of the base material.

2. Thin welding thickness

The controllable melting temperature is 0.1-0.8mm, so aluminum alloy thin plates below 0.2mm can be welded.

3. High degree of integration

This machine belongs to metallurgical bonding, and the bonding strength after welding is high. It can adapt to various processing forms without falling off.

4. High repair welding efficiency

Automatic wire feeding is adopted. The diameter welding wire is 0.8-1.2mm & the welding spot diameter is 1.6-2.0mm. Instant heating, short solder joint formation time.

Scope of application

Pressure vessels have welds or pores after weldings, such as arresters, expanders, and other ships.

Such as cylinder head, suction pipe, shell, communication equipment shell.

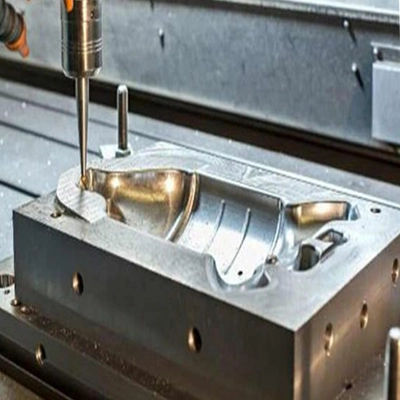

Repair of wear and tear of aluminum alloy molds, such as the lines on aluminum alloy shoe molds, repair of signs of wear, etc.

Repair the defects of various aluminum alloy materials.