Overview

Die casting parts are made from the die casting process. This is a die-casting machine equipped with a casting mould to pour the heated liquid copper, zinc, aluminum or aluminum alloy into the inlet of the die-casting machine, and then die-cast it by the die-casting machine. Thereby, copper, zinc, aluminum parts or aluminum alloy parts of the shape and size restricted by the mould are cast. Such parts are usually called die casting parts.

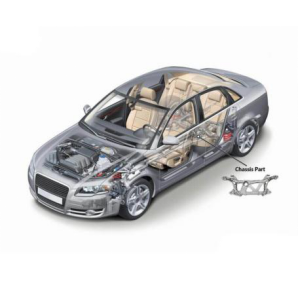

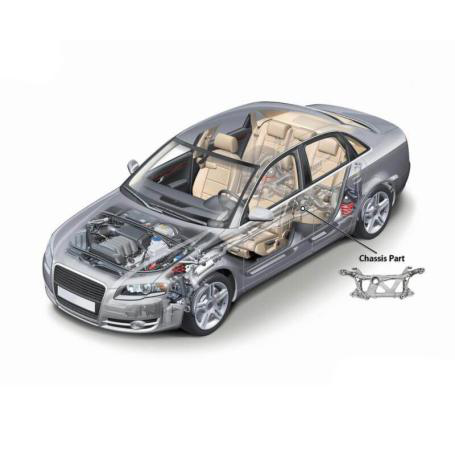

Application of Aluminum Die Casting Parts

Aluminum alloy die castings are a popular product in the die casting industry today. Because aluminum has the advantages of thermal conductivity and lightweight, it is widely used in automobile manufacturing, internal combustion engine, electric motor, oil pump manufacturing, electronic communication parts production, and other industries. Our company has aluminum alloy die-casting technology suitable for various industries, mainly for automotive die-casting parts and telecommunication, motor housing, electric vehicle battery housing die-casting parts, and so on.

Summary

Because aluminum alloy has good fluidity and plasticity, and the casting process is cast in a pressure die casting machine, aluminum die castings can be made into various complex shapes, which are suitable for the production of die castings in many industries. In addition, aluminum alloy die castings can be made with higher precision and smoothness, which greatly reduces the amount of machining of the castings and the casting allowance of aluminum alloy. Therefore aluminum alloy die castings not only saves electricity and metal materials but also greatly saves labour costs.