ADC12 is a Japanese brand, also known as No.12 aluminum material. Al-Si-Cu series alloy is a die-cast aluminum alloy, suitable for cylinder head cover, sensor, bracket, cylinder block, motor cover/housing, etc., the implementation standard is JIS H 5302-2000.

1. Material composition

JIS Standard | Cu | Si | Mg | Zn | Fe | Mn | Ni | Sn | Al |

ADC12 | 1.5-3.5 | 9.6-12.0 | <0.3 | <1.0 | <1.3 | <0.5 | <0.5 | ≤0.2 | Remain |

2. Mechanical Properties

Alloy | Tensile strength | Hardness test | ||||||||||||

Tensile strength MPa | Endurance MPa | Elongation % | HB | HEB | ||||||||||

average value | σ | ASTM | average value | σ | ASTM | average value | σ | ASTM | average value | σ | ASTM | average value | σ | |

ADC12 | 228 | 41 | 310 | 154 | 14 | 150 | 1.4 | 0.8 | 3.5 | 74.1 | 1.5 | 86 | 40 | 1.8 |

3. Physical Properties

Material | Alloy | Density | Thermal Conductivity | Coefficient of Thermal Expansion | Electrical Conductivity | Process | |

Unit | g/cm3 | °C | W / m K | µm/m°K | % IACS | ||

Aluminum Die Casting Metals | 2.74 | 549 | 96 | 21.1 | 23.0 | Cold Chamber Die Casting |

4. Application

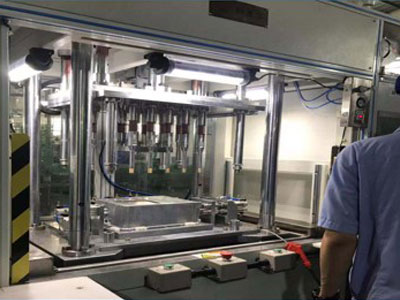

ADC12 material has a wide range of applications and can be applied to cylinder head cover, sensor bracket, cover, cylinder block, motor cover/housing, etc.

5. Advantages

Excellent mechanical properties

Good fluidity and filling

Good machinability

Generally good corrosion resistance

The draft angle is small

Good dimensional accuracy and stable size

Good surface treatment characteristics