Aluminum die casting has transformed the automotive industry. Manufacturers increasingly rely on it to create lightweight, durable auto parts. The need for high-quality components drives auto manufacturers to seek expert aluminum die casting services.

Automakers are always looking to make vehicles lighter. Using aluminum is a key strategy here. Lighter cars use less fuel. This means better gas mileage and lower emissions, which help the environment.

Aluminum is recyclable, making it a green choice. Recycling aluminum uses only a fraction of the energy required to make new aluminum. This significantly lowers the carbon footprint associated with automotive manufacturing.

While aluminum may have a higher upfront cost, its lightweight nature can lead to long-term savings. Fuel efficiency translates to lower operating costs, making aluminum components a smart investment.

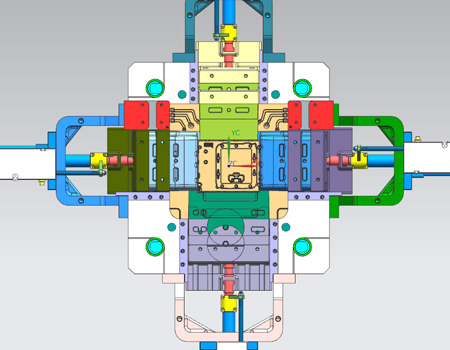

The die casting process begins with design. Engineers use CAD/CAM technology to make precise models. Choosing the right aluminum alloy is essential for durability.

Mold Creation: A mold is made based on the design.

Metal Injection: Aluminum is heated and injected into the mold.

Cooling and Solidification: The metal cools and hardens into the desired shape.

Finishing: Additional machining or finishing processes improve the surface quality.

X-ray testing: To check for internal flaws.

Dimensional checks: Ensuring parts meet design specifications.

Aluminum die casting is used in many engine components. Engine blocks and cylinder heads benefit from aluminum’s lightweight nature and strength.

Transmission housings made from aluminum reduce the weight of the vehicle while maintaining strength. Aluminum die casting offers precise shapes for complex internal components.

Chassis parts made from die-cast aluminum provide excellent support and durability. This includes brackets and suspension systems designed to withstand daily use.

When searching for a manufacturer, consider their experience. Companies with a history in die casting will have refined processes and expertise.

Look for manufacturers with industry certifications, such as ISO 9001. These standards assure quality and reliability.

Ensure the manufacturer can handle your production volume. Scalability is crucial for accommodating growth or increasing orders.

Technological advancements are shaping the future. Automation and new techniques improve efficiency and accuracy in die casting processes.

The industry is focusing on sustainability. More manufacturers are adopting eco-friendly practices to reduce waste and emissions during production.

As vehicles evolve, new applications for aluminum die casting are emerging. Electrification and autonomous technology will drive demand for lightweight components.