The die casting includes high pressure die casting(HPDC), low pressure dies casting(LPDC), Squeeze casting, gravity(GDC), an EMP is specialized in high pressure die casting, which is most commonly used for automotive, telecommunication, industrial etc.

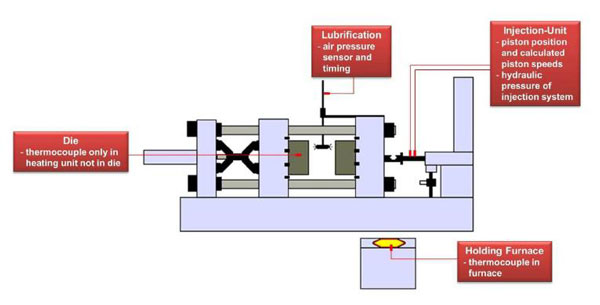

The die-casting machine is generally divided into cold chamber die-casting machines and hot-chamber die-casting machines.

The cold chamber die-casting machine is divided into the horizontal die-casting machine and vertical die-casting machine according to its chamber structure and layout.

Below is the flow chart for the high pressure die casting process:raw material-melting-die casting-dating-deburring-trimming-shot blasting-CNC machining-leak test-cleaning-full inspection-packing-delivery

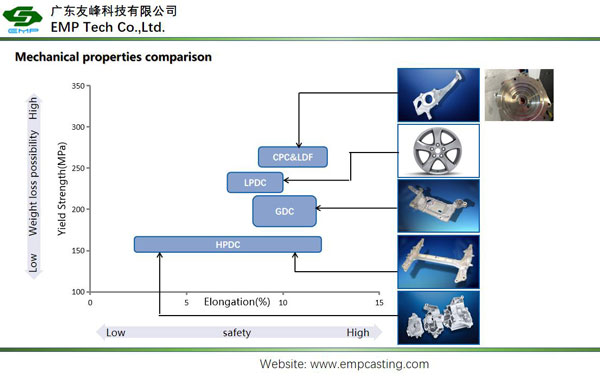

Die Casting Comparison

1. Process characteristics comparison

Casting Process | Process | Tooling Cost | Tooling Life | Porosity | Heat treatment | Allowance | Surface cleaning | Part | Productivity |

HPDC | Complex | High | Short | Poor | No | Small | High | Thin-wall | High |

Squeeze Casting | Complex | High | Short | Good | Yes | Small | High | thick-wall | High |

GDC | Simple | Low | Long | Good | Yes | Large | Low | thick-wall | Low |

CPC | Simple | Low | Long | Good | Yes | Large | High | thick-wall | Middle |

LPDC | Simple | Low | Long | Good | Yes | Large | Middle | thick-wall | Middle |

2. Mechanical Properties Comparison