Aluminum heat sink is an indispensable heat dissipation component in electronic equipment, its heat dissipation efficiency is directly related to the performance and stability of the equipment. And die casting aluminum radiator technology as a kind of high-efficiency, accurate manufacturing process, for improving the efficiency of aluminum heat sinks has a significant role. This article will be from three aspects of the analysis of die-casting aluminum radiator technology and how to improve efficiency.

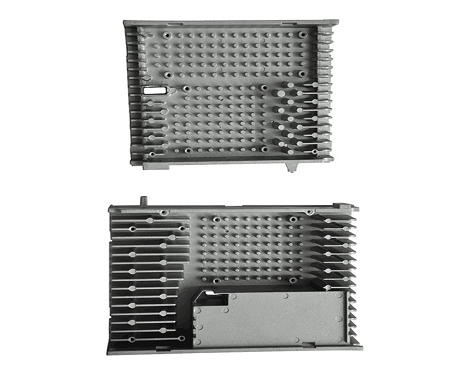

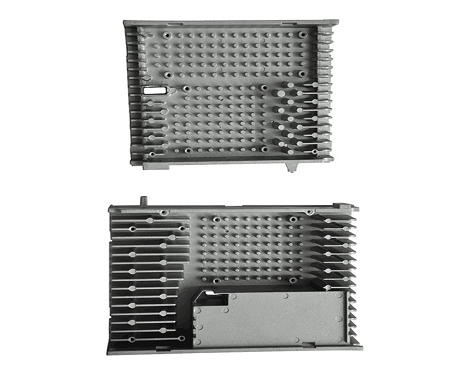

Die-casting aluminum radiator technology has a high degree of design flexibility, and can produce complex shapes, and fine structures of aluminum radiators. Reasonable structure design, can increase the heat dissipation area of the radiator, so as to improve the heat dissipation efficiency. For example, the use of multi-piece or finned structure design can increase the surface area of the radiator, so that it better heat exchange with the air.

Die-casting aluminum radiator technology can achieve high-precision dimensional control, to ensure that the various parts of the aluminum radiator size are accurate, and close. This helps to reduce thermal resistance and improve the efficiency of heat transfer. At the same time, accurate size control can also ensure good contact between the radiator and other parts of the equipment, reducing the loss of the heat transfer process.

Die-casting aluminum radiator technology also has high efficiency, and mass production characteristics, and can meet the market demand for aluminum radiators. The realization of mass production, can reduce production costs and energy consumption, at the same time ensure the consistency and stability of product quality. This not only helps to improve the market competitiveness of die casting automobile parts but also can provide a strong guarantee for the stable operation of the equipment.

In summary, die-casting aluminum radiator technology can significantly improve the efficiency of aluminum radiators by optimizing the structural design, precise control of size, and achieving mass production. In practical application, we can choose the appropriate die-casting process and material according to the specific needs and application scenarios, in order to realize the best heat dissipation effect. At the same time, with the continuous progress and innovation of technology, die-casting aluminum radiator technology will play a more important role in the field of aluminum radiator manufacturing, for the performance and stability of electronic equipment to provide more reliable protection. Click to learn more from the top aluminium die casting manufacturer China.