The automotive industry is rapidly evolving, driven by demands for lightweight, durable, and cost-effective components. As vehicles become more advanced—especially with the rise of electric vehicles (EVs)—the need for high-quality auto parts die casting solutions has never been greater. At EMP Die Casting, we specialize in delivering cutting-edge die casting services tailored to meet the stringent requirements of modern automotive manufacturing.

Lightweight Design: Automotive aluminum die casting reduces vehicle weight, enhancing fuel efficiency and EV battery performance.

Cost Efficiency: High-volume production capabilities lower per-unit costs while maintaining consistency.

Complex Geometries: Intricate components like engine blocks, transmission housings, and EV motor controllers can be produced in a single step, minimizing post-processing.

Durability: Aluminum alloys (e.g., ADC12, A380) offer excellent thermal and mechanical resistance, ideal for harsh automotive environments.

The global die casting market is projected to grow at a 7.3% CAGR from 2024 to 2031, reflecting its pivotal role in automotive innovation.

At EMP Die Casting, we combine decades of expertise with state-of-the-art technology to address the automotive industry’s toughest challenges. Here’s what sets us apart:

1. Precision Engineering for EV and Traditional Automotive Systems

Our solutions cater to both conventional and electric vehicles. For example, our EV Motor Controller Housings are engineered to protect sensitive electronics while ensuring optimal thermal management. Made from high-performance aluminum alloys, these housings meet rigorous safety and efficiency standards, supporting brands like Daimler and Continental.

2. State-of-the-Art Facilities

Quality Assurance: IATF 16949 (VDA6.3) certification and a dedicated QC team (30% of our workforce) guarantee defect-free components.

3. End-to-End Service

From tooling design to CNC machining and leak testing, we provide a seamless, one-stop service. Our R&D team, with over 8 years of EV industry experience, collaborates closely with clients to refine designs and accelerate time-to-market. Sampling and mold production are completed in under 50 days, ensuring you stay ahead of competitors.

4. Solving Industry Pain Points

Surface Treatments: While traditional aluminum die casting by China aluminum die casting parts manufacturers struggles with anodizing, we offer advanced coatings (e.g., powder coating,passivation treatment) for aesthetics and corrosion resistance.

Engine and Transmission Parts: Cylinder heads, gearbox cases, and oil pans.

Structural Components: Lightweight chassis parts and suspension systems.

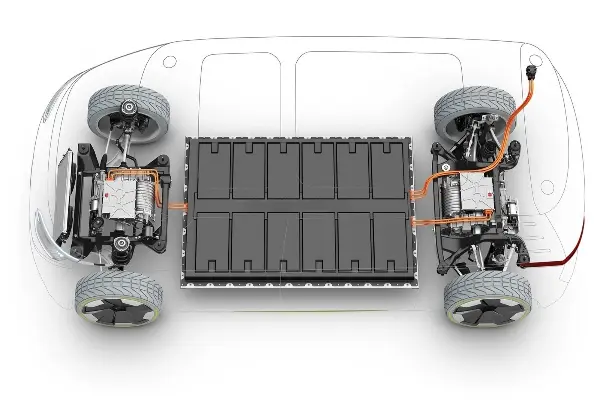

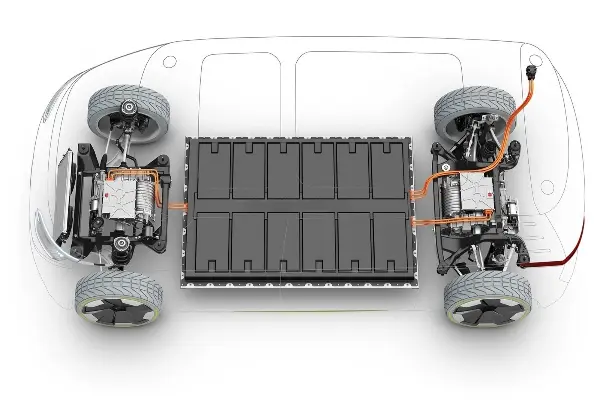

EV-Specific Solutions: Battery housings, inverter casings, and charging port assemblies.

These components are trusted by global automotive leaders, underscoring our commitment to quality and innovation.

Material Innovation: Development of high-strength, recyclable alloys to reduce environmental impact.

Smart Manufacturing: Integration of AI and IoT for real-time process optimization .

Customization: Flexible production lines to accommodate low-volume, high-mix EV part demands.

Proven Expertise: Over a decade of serving top-tier automotive brands.

Competitive Pricing: Cost-effective solutions without compromising quality.

24/7 Support: Rapid response to inquiries and technical challenges.

In an era where precision and efficiency define automotive success, EMP Tech Die Casting stands as your trusted partner. Whether you’re developing next-gen EVs or optimizing traditional vehicles, our auto parts die casting solutions deliver unmatched performance, reliability, and value.

Ready to elevate your automotive projects? Contact EMP Die Casting today to discuss custom solutions tailored to your needs.