Current industry status of die-cast motor case processing

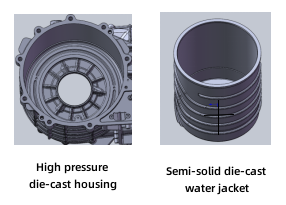

The water-cooled die-cast motor housing is generally composed of two die-cast parts: the outer shell and the water jacket. After a series of processes such as welding processing, hot jacket combination, stir friction welding, post-welding processing and testing, a sealed water-cooled cavity motor housing is finally formed.

The die-casting of motor shells generally use high-pressure casting process, but high-pressure casting has a process defect, that is, in the casting process is easy to get involved in the airflow, molding pore shrinkage, heat treatment will also be bubbling, which brings a lot of safety risks to the motor shell, at present, the industry's die-casting motor shell qualification rate is only 70%, the scrap rate is very high.

Improvement solution for die-cast motor case processing

The water jacket is the core part of the die-cast motor shell, nesting the motor stator, to ensure the normal operation of the rotor, its airtightness, force performance and concentricity directly affect the safety performance of the motor, therefore, we improve the die-cast motor shell process scheme according to the water jacket molding and welding process.

For the traditional die-casting molding porosity problem we choose the new semi-solid die-casting molding water jacket, by pulling the semi-solid die-casting motor shell water jacket compared to the existing technology of die-casting or casting molding water jacket, has excellent air tightness and force performance, while using advanced stirring friction welding process to complete the flow channel sealing cavity, to ensure the normal and safe operation of the motor work.