Die casting is a critical manufacturing process used across industries to produce high-quality, precision metal parts. As global demand for lightweight and durable components grows, die casting companies play an increasingly vital role in automotive, aerospace, electronics, and consumer goods. In this article, we explore the top die casting companies worldwide, the different types of die casting, material selection, and how to choose the best die casting companies in China, including industry leader EMP Die Casting.

Die casting can be categorized into two primary methods:

1. High-Pressure Die Casting (HPDC)

Uses high pressure to force molten metal into a steel mold

Ideal for high-volume production with tight tolerances

Commonly used for aluminum die casting auto parts and consumer electronics

2. Low-Pressure Die Casting (LPDC)

Utilizes lower pressure, reducing porosity in the final product

Better for larger, thicker components

Often used in aerospace and automotive structural parts

Additionally, gravity die casting and squeeze casting are specialized methods used for specific applications.

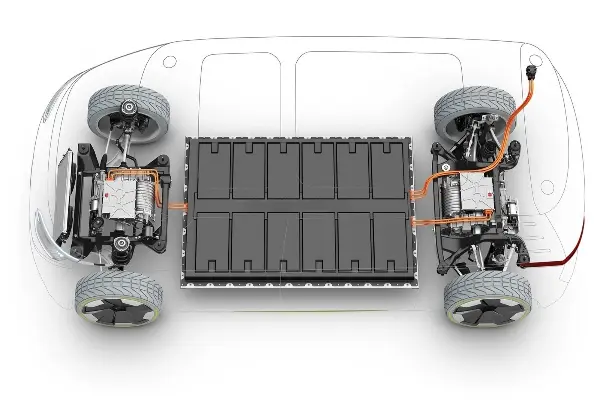

High-pressure die casting (HPDC) dominates the industry due to its efficiency, precision, and scalability. It is particularly favored in automotive manufacturing for producing:

Engine blocks

Transmission housings

Wheel spacers

Bracket components

China has emerged as a global leader in HPDC, with die casting China companies like EMP Die Casting supplying high-quality parts to international markets.

The choice of material depends on the application, but the most commonly used metals include:

1. Aluminum

Lightweight, corrosion-resistant, and excellent thermal conductivity

Widely used in aluminum die casting auto parts and electronics

2. Zinc

High ductility and strength, ideal for intricate designs

Common in consumer electronics and hardware

3. Magnesium

The lightest structural metal, perfect for aerospace and portable devices

Requires careful handling due to flammability

4. Copper & Brass

Used for high-conductivity components in electrical systems

China precision die casting manufacturers like EMP Die Casting specialize in aluminum and zinc alloys, offering superior surface finishes and dimensional accuracy.

Choosing the right die casting companies in China requires careful evaluation of several factors:

1. Industry Experience & Reputation

Look for suppliers with a proven track record in your industry

Check certifications (ISO, IATF 16949 for automotive)

2. Manufacturing Capabilities

Evaluate their machinery, production capacity, and quality control

EMP Die Casting, for example, uses advanced CNC machining for high-precision parts

3. Material Expertise

Ensure they work with the alloys required for your project

4. Cost & Lead Time

Compare pricing while ensuring quality isn’t compromised

Reliable suppliers offer competitive pricing without long delays

5. Customization & Prototyping

The best die casting China companies provide design support and rapid prototyping

While China leads in cost-effective and high-volume production, several global players stand out:

1. EMP Die Casting (China)

Specializes in aluminum die casting auto parts and precision components

Offers end-to-end solutions from design to finishing

2. Dynacast (International)

Known for small, intricate zinc die-cast parts

3. Gibbs Die Casting (USA)

Major supplier for the automotive industry

4. Ryobi Die Casting (Japan)

High-quality aluminum die casting for electronics and automotive

5. Martinrea Honsel (Germany)

Focuses on lightweight automotive solutions

China remains the top destination for die casting due to:

Cost Efficiency – Competitive pricing without sacrificing quality

Advanced Technology – Adoption of automation and Industry 4.0 practices

Scalability – Ability to handle high-volume orders

Supply Chain Advantages – Access to raw materials and skilled labor

EMP Die Casting exemplifies these benefits, providing china precision die casting services to global clients.

Selecting the right die casting supplier is crucial for product quality and cost efficiency. While many die casting companies in China offer competitive services, EMP Die Casting stands out with its expertise in aluminum die casting auto parts, precision manufacturing, and reliable supply chain solutions. Whether you need high-volume production or custom prototypes, partnering with an experienced die casting company ensures superior results.

For businesses seeking top-tier china precision die casting, evaluating experience, capabilities, and material expertise will lead to the best manufacturing partner.